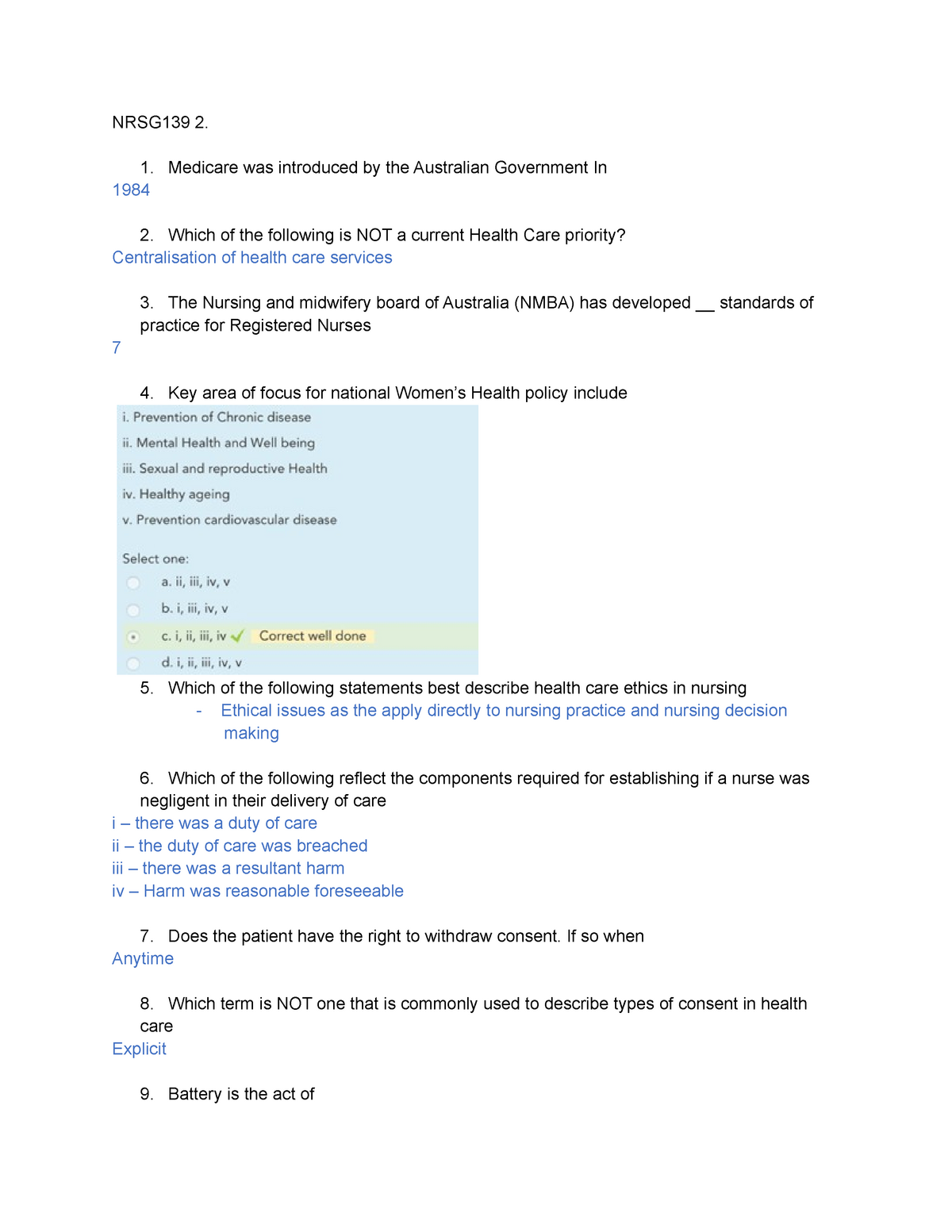

Earn an overall score of 80% or better on the IPC written examinations in order for certification. Explain IPC terminology and definitions Be able to proficiently conduct Certified IPC Specialist (CIS) training

Be able to reference the IPC J-STD-001 GS Space Application standard BEST offers the Space Application certification training after every regularly scheduled IPC J-STD-001 Certified IPC Trainer (CIT) Course COURSE OBJECTIVE * All attendees must be certified to the IPC J-STD-001G. It provides additional requirements over those published in the IPC J-STD-001G to ensure the reliability of soldered electrical and electronic assemblies that must survive the vibration and thermal cyclic environments experiences while traveling and operating in space. The IPC J-STD-001 GS Course can be added as an optional Module 6 to the IPC J-STD-001 Training & Certification Program. Suppliers to NASA are required to have workers trained and certified to this IPC J-STD-001 GS course for Specialist (CIS) level training. The IPC J-STD-001 GS training combines the Requirements for Soldered Electrical and Electronic Assemblies along with various elements to meet the standards required of NASA suppliers.

Ipc j std 001g practice test portable#

The IPC J-STD-001 Certified IPC Specialist (CIS) Course provides individuals with a portable credential that recognizes their soldering skills and understanding of this internationally recognized standard. Certification helps enhance individual skills and performance. The IPC J-STD-001 training program focuses on the knowledge and hand skills that individuals need to produce high-quality soldered interconnections. The IPC J-STD-001 training program consists of both hand soldering as well as learning the material in the J-STD-001 specification related to various assembly methods. It emphasizes process control and establishes industry-consensus requirements for a broad range of electrical connections.

Ipc j std 001g practice test verification#

The standard describes materials, methods, and verification criteria for producing high-quality soldered leaded and lead-free interconnections. However, vertical fill in the barrel of the plated through-holes was too close to the IPC-A-610 minimum specification of 75% to determine a pass/fail condition, and therefore required further investigation.IPC J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies ,has emerged as the preeminent authority for electronics assembly manufacturing worldwide. The first inspection was to investigate the capacitor leads using optical microscopy, and no anomalies were found that could indicate bad parts from the vendor or improper handling prior to assembly.

These analyses enabled ACI to verify the elements comprising the solder joints and make the following recommendations in order to prevent future occurrences. Upon receipt of the samples, ACI performed three levels of inspection and Energy Dispersive Spectroscopy (EDS) testing to investigate the root cause of the failures. The components were experiencing failures following vibration and accelerated stress testing.

Applications and requirements specified in J-STD-001 are divided into three classes based on the nature of their end use. Recently, an ACI Technologies (ACI) customer called to discuss failures that they had observed with some through-hole capacitor parts. J-STD-001 is an industry standard guide for electrical and electronic assemblies detailing practices and requirements for solder joint manufacturing. Per the information provided in IPC J-STD-001 I submit the following: J-STD-001. Investigation of Through-Hole Capacitor Parts Failures Following Vibration and Stress Testing Leo Lambert has submitted responses to the following questions.

0 kommentar(er)

0 kommentar(er)